Aerobic Biodegradation Test for Plastics

This test method measures the degree of disintegration of plastic materials exposed to a composting environment. Disintegration refers to the physical breakdown of the material into tiny fragments. Biodegradation is the phenomenon where organic substances are ultimately broken down by microorganisms into carbon dioxide and water. Therefore, it is important to note that claiming biodegradability based solely on the results of this test method may not be warranted.

Standard Number

ISO 20200 (JIS K 6954)

Standard Title

Plastics – Measurement of the Disintegration of Plastic Materials under Laboratory-Simulated Composting Conditions

Overview

This test measures the disintegration of test materials in a laboratory setting under simulated aerobic composting conditions. The solid medium used is a synthetic solid waste obtained from mature compost from a municipal or industrial composting plant. The plastic test materials are composted within this adjusted solid medium. After the composting cycle, the medium at the end of composting is sieved with a 2mm sieve to collect the remaining undegraded residue, and the degree of disintegration is measured. The mass loss of the test material is considered as the disintegrated material and is used in the calculation of disintegration.

Inoculum Source

Synthetic Solid Waste

| Material | Dry Mass(%) |

| Sawdust | 40 |

| Rabbit Feed | 30 |

| Mature Compost | 10 |

| Starch | 10 |

| Sucrose (Table Sugar) | 5 |

| Corn Oil | 4 |

| Urea | 1 |

| Total | 100 |

Sample Shape

Dimensions of Test Pieces Used in Disintegration Test

| Thickness of Test Material | Dimensions of Test Piece (Height × Width × Thickness: mm) |

| Less than 5mm | 25×25×thickness of test material |

| 5mm or more | 15×15×(5-15 thickness) |

Pretreatment: Dry in a vacuum dryer at 40±2°C until a constant weight is achieved, then immerse in distilled water for 30 seconds before testing.

The proportion of the test material to wet synthetic solid waste should be in the range of mass fraction 0.5-2%.

Test (Composting) Container

Recommended Container: Made of PP with dimensions of 30cm × 20cm × 10cm (Height × Width × Depth).

To avoid excessive moisture evaporation, the lid should be airtight-sealed.

Drill a hole with a diameter of 5mm approximately 6.5cm from the bottom of the container at the center of the two sides with a length of 20cm. Do not plug these two holes, as they facilitate gas exchange between the compost interior and the external environment.

Test Temperature

① 58±2°C (High-temperature incubation period)

② 25±2°C (Mid-temperature incubation period)

Generally, the test is conducted at ①, but if the disintegration is insufficient after 90 days, the mid-temperature incubation period at ② can be extended.

Test Duration

① Up to 90 days

② Up to 90 days

Composting Procedure

High-temperature Incubation Period

| Elapsed Time (Days) | Procedure |

| 0 | Measure the initial mass of the reactor. |

| 1, 2, 3, 4, 7, 9, 11, 14 | Measure the mass of the reactor, add water as needed to return to the initial mass, and mix the compost. |

| 8, 10, 16, 18, 21, 23, 25, 28 | Measure the mass of the reactor, add water as needed to return to the initial mass, and do not mix the compost. |

| 30, 45 | Measure the mass of the reactor, add water as needed to reach 80% of the initial mass, and mix the compost. |

| 30-60 days (twice a week) | Measure the mass of the reactor, add water as needed to reach 80% of the initial mass, and mix the compost. |

| Beyond 60 days (twice a week) | Measure the mass of the reactor, add water as needed to reach 70% of the initial mass, and mix the compost. |

Diagnostic Parameters

■Smell

During the composting process, distinct and characteristic odor changes can be detected. In the first 2-3 days after the test starts, synthetic waste emits a sour odor (acetic acid smell), gradually transitioning to an ammonia odor around 5-10 days, lasting for approximately 10 days. Eventually, it becomes odorless or has an earthy smell.

■Appearance

The appearance of the compost changes during the initial 2 weeks. Mycelium growth on the compost is typically visible within the first week. As synthetic waste contains a high concentration of sawdust, it is initially bright yellow but changes to brown within 10 days.

■Chemical Analysis

To measure the initial and final total carbon/total nitrogen ratio (C/N ratio) and pH values, samples of synthetic waste used at the beginning of the test and compost obtained at the end of the composting process are sieved, analyzed for composition, and pH is measured.

■Measurement of Dry Mass and Volatile Solid Content

Sieve and measure the dry mass and volatile solid content of synthetic waste used at the beginning of the test and compost samples obtained at the end of the composting process.

Measurement

Mass:

Using sieves according to ISO 3310 standards, start with a 10mm diameter sieve and sieve the compost from each reactor. Examine the fragments of the test material left on this sieve. Pass the compost particles through a sieve to collect fragments with a particle size less than 10mm. Collect and store the fragments that did not pass through a 10mm sieve. Repeat the procedure using 5mm and 2mm diameter sieves sequentially to sieve the compost. Collect each test material collected at the sieving stage, drop the compost, wash if necessary by soaking in water, and finally, dry the test material in a vacuum at 40±2°C until a constant weight is reached. Record the final mass.

Evaluation

Calculation of Disintegration

Plastic materials recovered from the sieving procedure are considered undegraded materials. Materials that pass through the sieve are considered degraded.

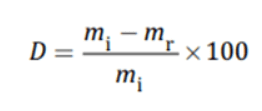

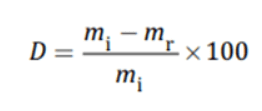

The disintegration degree (D) is calculated as a percentage using the following formula:

D is the disintegration degree in percentage.

mi is the initial dry mass of the test material.

mr is the dry mass of the remaining test material left on the sieve.

Calculate the disintegration degree individually for each reactor.